-

Overview

Flyer - Component Matrix

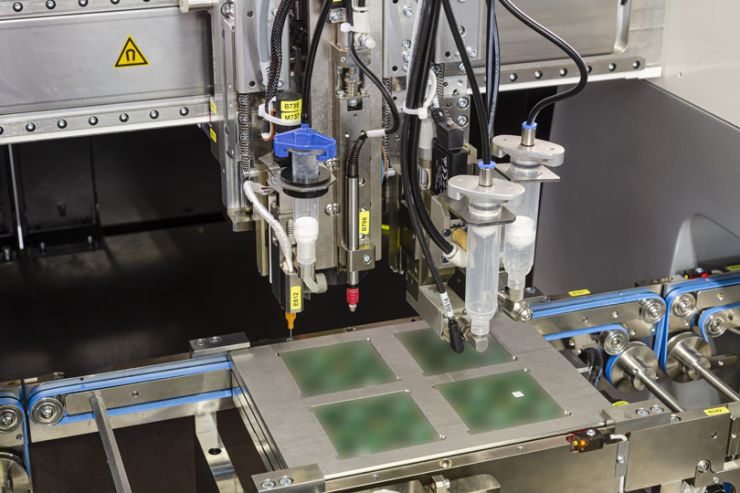

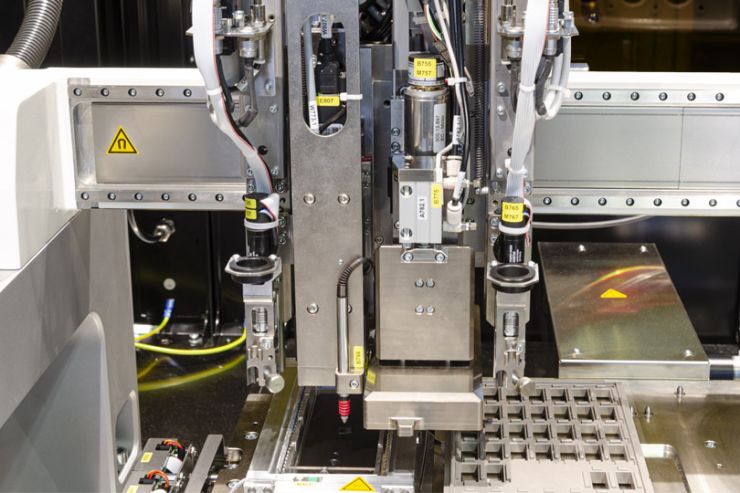

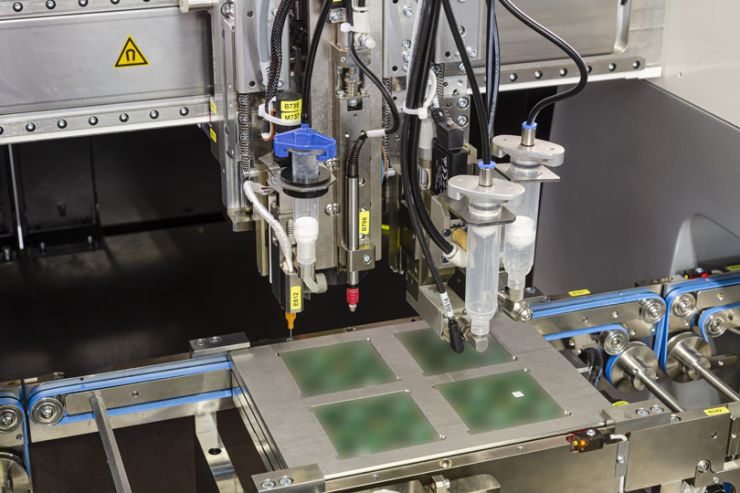

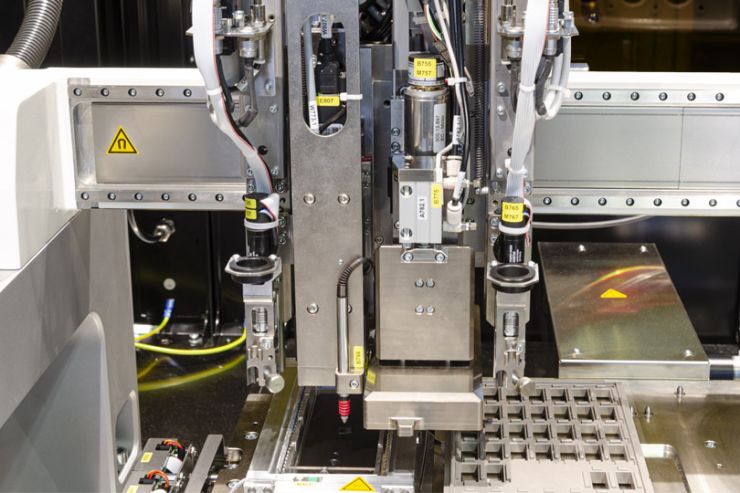

The Infotech Componet Matrix offers a wide range of head peripherlas which can be combined with each other depending on our customers needs. For example cameras, assembly heads, ultrasonic- and thermo-bonding heads and dispensing units.

The applied modules are customized and optimized according to customer requirements without affecting their basic functions. -

Flexibility

Flyer - Component Matrix

The interaction between different assembly heads, axis systems and vision systems allows us to solve even the most complex assembly tasks without involving special machine engineering. This flexibility is very central to the user/customer because even difficult tasks can be solved with low financial and timing risks.

The modules of the Infotech Component Matrix can be adapted according to the application requirements and optimized to the process without affecting the basic functions. -

Efficiency

Infotech machines are not only working very precisely but also rapidly. The head configuration is always adapted to the performance requirements so that the utilization can be maximized based on the available floor space.

In addition to the head camera, up to six assembly heads or three dispensing axes can be configured directly onto the robot head. Each unit works autonomously so that multiple parts or different dispensing media can be handled simultaneously on the same machine.

-

Compactness

Floor space costs money! Especially in clean rooms, where spatial conditions are tight and expensive. We build our robot heads with the highest possible compactness. Multiple process requirements such as assembling, dispensing, measuring, curing etc. can be mounted jointly, minimizing space without losing functionality or reliability. This compactness allows us to provide a complete production process on fewer machines than is possible with standard equipment.

Dispensing heads have a minimal grid of 20 mm depending on the used dispensing technique. Assembly heads with a grid of only 17 mm are even more compact.

-

Image Processing

A camera unit is always mounted onto the robot head, possible additions are dispensing axes and other head peripherals. On the one hand, the camera is used for the location of substrates, workpieces, fiducial marks, etc. And on the other, this camera allows for the execution of automated calibration routines, postbond inspections or other process surveillance tasks.

The underlying vision software is completely embedded in the graphical user interface of the machine control and offers a versatile and flexible tool library.

Different adjustable illumination parameters ensure that any structure is identified reliably. Vision processes with their assigned models are always a part of a manufacturing program and do not have to be called up separately. The vision system is therefore an indispensable part of all processes which are realized on Infotech machines.

-

Overview

Flyer - Component Matrix

The Infotech Componet Matrix offers a wide range of head peripherlas which can be combined with each other depending on our customers needs. For example cameras, assembly heads, ultrasonic- and thermo-bonding heads and dispensing units.

The applied modules are customized and optimized according to customer requirements without affecting their basic functions. -

Flexibility

Flyer - Component Matrix

The interaction between different assembly heads, axis systems and vision systems allows us to solve even the most complex assembly tasks without involving special machine engineering. This flexibility is very central to the user/customer because even difficult tasks can be solved with low financial and timing risks.

The modules of the Infotech Component Matrix can be adapted according to the application requirements and optimized to the process without affecting the basic functions. -

Efficiency

Infotech machines are not only working very precisely but also rapidly. The head configuration is always adapted to the performance requirements so that the utilization can be maximized based on the available floor space.

In addition to the head camera, up to six assembly heads or three dispensing axes can be configured directly onto the robot head. Each unit works autonomously so that multiple parts or different dispensing media can be handled simultaneously on the same machine.

-

Compactness

Floor space costs money! Especially in clean rooms, where spatial conditions are tight and expensive. We build our robot heads with the highest possible compactness. Multiple process requirements such as assembling, dispensing, measuring, curing etc. can be mounted jointly, minimizing space without losing functionality or reliability. This compactness allows us to provide a complete production process on fewer machines than is possible with standard equipment.

Dispensing heads have a minimal grid of 20 mm depending on the used dispensing technique. Assembly heads with a grid of only 17 mm are even more compact.

-

Image Processing

A camera unit is always mounted onto the robot head, possible additions are dispensing axes and other head peripherals. On the one hand, the camera is used for the location of substrates, workpieces, fiducial marks, etc. And on the other, this camera allows for the execution of automated calibration routines, postbond inspections or other process surveillance tasks.

The underlying vision software is completely embedded in the graphical user interface of the machine control and offers a versatile and flexible tool library.

Different adjustable illumination parameters ensure that any structure is identified reliably. Vision processes with their assigned models are always a part of a manufacturing program and do not have to be called up separately. The vision system is therefore an indispensable part of all processes which are realized on Infotech machines.